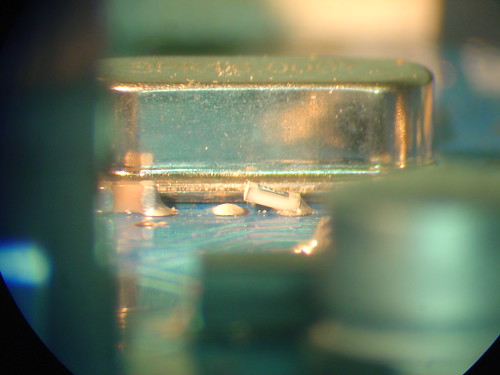

That’s a closeup of resistor R1 on my new Arduino Uno board. See how the left terminal isn’t touching the solder bump on the land pad? That’s not good.

Surprisingly, my Arduino seems to work just fine with one side of the resistor open. Arduino, don’t let the cost reduction guys see this one, or they’ll eliminate it in the next rev!

More photos of the tombstoned resistor on my Arduino Uno.

The Arduino team has responded to other claims of manufacturing defects (most of which seem fairly trivial) in their blog post “One bad Arduino doesn’t spoil the barrel“. I have already contacted my reseller and will do everything possible to help Arduino improve their manufacturing process and quality control.

I took a closer look at the pads on an older Deumilanove and, based on the pics of the Uno, I think it’s a pad shape/size issue.

Tombstoning typically occurs when the paste at one end of a component reflows before the other end- the liquid solder wets up the side of the component, which applies a torque and tries to lift the other end. It’s simple physics- the longer the pad is away from the base of the component, the more torque the wetting solder can apply, and the more likely tombstoning is to occur.

That’s why IPC specs for component footprints include not just minimum pad sizes but maximum sizes as well.

That’s a great little piece of lore, Mike. Thanks!

Mike,

The pads do appear to be too large for the resistor, based on my experience with the IPC standards. The Arduino team likes round pads, which I think are suggested for use with Pb-free solder, but I guess just being round wasn’t enough to avoid a problem in this case.

I believe that tombstoning often occurs when one pad is connected to a large trace, like a power plane, and the other side is connected to a skinny signal trace. The difference in thermal mass between the pads causes the problem you describe. I have also read that oversized pads can cause the issue because the component can easily shift off center and pull one end off its land. That looks like what happened here.

It’s also worth pointing out that the SMT component footprints that ship with Eagle are much, much too large. One of the first things I did when I started using Eagle was to create my own Eagle library based on IPC’s guidelines. I haven’t had any issues with either sets of lands, but I haven’t done any large scale manufacturing either!

I don’t think the Arduino team is using Eagle, but for everyone who does it’s a good thing to be aware of.

Needing a microscope doesn’t mean the problem is insignificant. It means manufacturing at this scale is more unforgiving.

Speaking of not belting folks, I want to do a little testimonial for another company.

I once had a problem with a Propeller board from Parallax, and I called early one morning. The tech who answered the phone said “This is Chip, how can I help you?” — and I explained that the Mini USB connector appeared to have been cold soldered and it had popped clean off the second time I tried to plug the cable in. We worked through his significant surprise and he shipped me a new board that morning, no waiting for the RMA to go through.

And I got off the phone, and then it hit me. “Chip”? Chip Gracey–one of the founders of Parallax and the driving force behind the Propeller project–was fielding tech support calls at o’God-o’clock in the AM. At least sometimes.

/That/ is the kind of CTO I aspire to be.

Michael,

Wow, that is really cool! Chip sounds strikingly different from most CTO’s I have met – down to earth and directly in touch with customers – awesome!

I think the thing is that he does it occasionally just to get a better sense of what customer complaints/concerns are. That’s better than down-to-earth. 😉

Again though this honestly doesnt reflect bad on the arduino guys. You did need a microscope to even show us.

Random guy,

I’m not sure how to interpret what you wrote. I admit that in my case, the tombstoned resistor does not seem to affect the operation of my Arduino Uno under nominal operating conditions. However, a broken connection is a broken connection, whether you need a microscope to see it or not. Regardless of the effect removing R1 has on the design, this board should not have passed QC, period.

I suspect that I am just unlucky and received one of the extremely small pool of bad boards the Arduino team mentions on their blog.

I also suspect that the Arduino team will continue to improve their PCB layout, manufacturing process, and/or their quality control inspection procedures in order to ensure that other customers don’t receive bad or suspect boards like mine.

Good on you for writing a fair article, and not belting the Arduino team.